Structural steel round bars

Hot rolled and forged round bars in steel grade S355J2

In the diameter range 115–300 mm, the material may be peeled or unpeeled. All round bars with a diameter exceeding 300 mm are peeled.

All S355J2 are not CE marked, depending on the supplier.

| Diameter: | 16–510 mm |

| Length: | 6 m |

| Material standard Hot rolled (mainly diameters ≤ 300 mm) | EN 10025-1+2 |

| Material standard Forged (mainly diameters >300 mm) | EN 10250-1+2 |

| Size and form standard Unpeeled and hot rolled | EN 10060 |

Hot rolled round bars in steel grades S235JR, S355J2

| Diameter: | 6–110 mm |

| Length: | 6 m (production length 5.8–6m, tolerance -0+200 mm) |

| Material standard: | EN 10025 |

| Size and form tolerance: | EN 10060 |

| Material certificate: | EN 10204 / 3.1 |

Cold drawn round bars in steel grade S355J2C+C h9

| Diameter: | 5–100 mm |

| Length: | 3 m (other end bevelled) or 6 m |

| Sulfur content: | S% = 0.02–0.04 |

| Tolerance class: | ISO 286-2 h9 |

| Standard: | EN 10277 |

| Material certificate: | EN 10204 / 3.1 |

Quenched and tempered steels

Quenched and tempered steels are common in mechanical engineering. Thanks to their hardness and resilience, they are suitable for a wide range of applications. Quenched and tempered steels are also well suited for surface tempering that improves the durability of the piece.

We stock quenched and tempered steels in two steel grades: 42CrMoS4+QT and 25CrMoS4+QT. In order to ensure good machining qualities, the sulfur content of the products has a lower limit.

25CrMoS4+QT, rolled

- Dimension range 22–120 mm.

- Product standard EN ISO 683-2.

- Rolled surface, tolerances according to EN 10060.

- Bar length 6 m

- Delivery condition quenched and tempered.

- Ultrasound inspected according to EN 10308, class 3 requirements.

- Material certificate EN 10204/3.1.

42CrMoS4+QT, peeled

- Dimension range 25–50 mm with 5 mm increments.

- Product standard EN ISO 683-2.

- Peeled, tolerance h9.

- Bar length 6 m.

- Delivery condition quenched and tempered.

- The mechanical characteristics meet the requirements of the ISO 898-1 standard, class 10.9.

- Ultrasound inspected according to EN 10308, class 3 requirements.

- Material certificate EN 10204/3.1.

42CrMoS4+QT, rolled

- Dimension range 20–300 mm.

- Product standard EN ISO 683-2.

- Usually surface rolled, tolerances according to EN 10060.

- Bar length 5.6–6.2 m.

- Delivery condition quenched and tempered.

- Grain size according to ISO 643 or ASTM E 112-96 min. 5.

- Purity requirements exceeding the standard.

- Ultrasound inspected according to EN 10308, class 3 requirements.

- Material certificate EN 10204/3.1.

42CrMoS4+QT, forged

- Dimension range 320–600 mm.

- Product standard EN 10250-3.

- Rough peeled surface -0/+3 mm.

- Delivery condition quenched and tempered.

- Grain size according to ISO 643 or ASTM E 112-96 min. 6.

- Purity requirements exceeding the standard.

- Ultrasound inspected according to EN 10228-3, class 3 requirements.

- Material certificate EN 10204/3.1.

Case hardening steels

Case hardening steels are common in power transmitting components and rolling components. The surface of the piece is hardened during the final heat treatment, while the inner part remains softer. This makes the piece resistant to both wear and load.

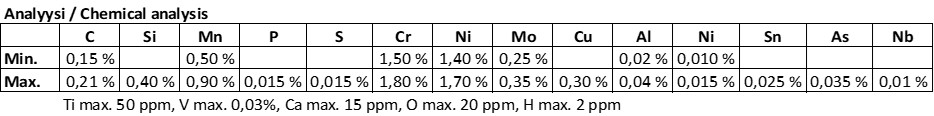

18CrNiMo7-6, rolled

- Dimension range 100–230 mm.

- Product standard EN ISO 683-3.

- Meets the requirements of ISO 6336-5 MQ quality.

- Usually surface rolled, tolerances according to EN 10060.

- Delivery condition annealed (+A or+FP).

- Requirements also for mechanical characteristics when quenched and tempered.

- Grain size according to ISO 643 or ASTM E 112-13 min. 6.

- Purity requirements exceeding the standard.

- Ultrasound inspected according to EN 10308, class 3 requirements, the surface zone according to class 4 requirements.

- Material certificate EN 10204/3.1.

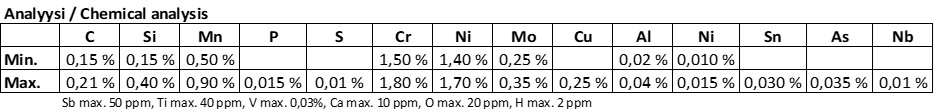

18CrNiMo7-6, forged

- Dimension range 230–880 mm. For bars over 630 mm, drilling at 100 mm.

- Product standard EN ISO 683-3.

- Meets the requirements of ISO 6336-5 MQ quality.

- Rough peeled surface -0/+3 mm.

- Delivery condition quenched and tempered (+QT).

- Requirements also for mechanical characteristics when quenched and tempered.

- Grain size according to ISO 643 or ASTM E 112-13 min. 6.

- Purity requirements exceeding the standard.

- Ultrasound inspected according to EN 10308, class 3 requirements, the surface zone according to class 4 requirements.

- Material certificate EN 10204/3.1.

Chromed bars

The most common application of chromed bars is in cylinder rods. The tolerance of the surface meets strict requirements, the chrome coating is extremely wear and corrosion resistant.

20MnV6

- Dimension range 40–100 mm.

- Thickness of the chrome layer min. 20 µm

- Corrosion resistance test ISO 9227 neutral spray test (NSS), value according to ISO 10289 min 9 / 200 h

- Diameter tolerance f7.

- Straightness tolerance 0.5 mm / 2,000 mm.

- Bar length 6 m.

In addition to the products presented here, we stock a wider range of structural, quenched and tempered and case hardening steels as custom items that meet customer-specific requirements.

Cast iron bars

Grey cast iron GJL-250C has excellent machining characteristics, and it is used in machine parts that are subject to lighter loads. The mechanical characteristics of spheroidal graphite cast iron GJS-500-7 are even better than those of simple mechanical steel grades. Its notch toughness, fatigue resistance and wear resistance are better than grey cast iron’s. Cast iron ahs excellent vibrodamping properties. We deliver cast iron bars without heat treatment.

GJL-250C

- Grey cast iron

- Dimension range 65–115 mm.

- Product standard EN 16482 (also DIN 1561)

- Bar length 3 m

Machining allowance

| 50 < ø ≤ 100 mm | 6 mm |

| 100 < ø ≤ 200 mm | 8 mm |

GJS-500-7

- Spheroidal graphite cast iron

- Dimension range 40–230 mm.

- Product standard EN 16482

- Bar length 3 m

Machining allowance

| 20 < ø ≤ 50 mm | 6 mm |

| 50 < ø ≤ 100 mm | 9 mm |

| 100 < ø ≤ 200 mm | 11 mm |

| 200 < ø ≤ 300 mm | 15 mm |